Choosing a Rigid-Flex PCB Manufacturer You Can Trust

Choosing a Rigid-Flex PCB Manufacturer

When you are developing electronic devices, it is essential to choose the right rigid flex manufacturer. By doing so, you will be able to bring your ideas to life and create cutting-edge products that are reliable and durable. However, deciding which manufacturer to work with can be a daunting task. Fortunately, there are some key tips that can help you make the best decision.

Start by doing your research. Take the time to read online reviews and speak with other electronics designers who have used rigid flex PCBs. Once you have narrowed down your options, request quotes from multiple manufacturers. Compare prices and pay close attention to the details provided by each company.

When comparing quotes, be sure to ask each flex rigid pcb manufacturer about their manufacturing process and turnaround times. Additionally, be sure to inquire about their warranty policy. This will give you a good idea of the level of quality you can expect from each company.

Choosing a Rigid-Flex PCB Manufacturer You Can Trust

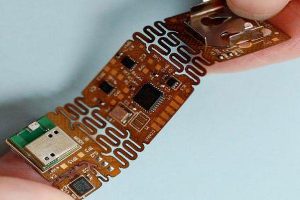

Rigid-Flex PCBs are ideal for applications that require a high degree of reliability, durability, and flexibility. They can be bent and folded to fit into small areas, and they can also be designed without solder joints or contact crimps. Additionally, they are able to withstand a variety of demanding environments, including high-temperature conditions.

During the manufacturing process, rigid-flex boards undergo strict electrical testing and verification. This ensures that the circuit board functions as intended and that it is safe to use in a variety of applications. This type of testing is particularly important for safety-critical devices, such as medical equipment and military missile guidance systems.

A rigid-flex PCB can be built with a number of different materials, including copper clad and polyimide. The latter material is often preferred due to its toughness and ability to withstand constant movements and vibrations. The rigid-flex PCB can also withstand high temperatures and a variety of harsh chemicals, radiation exposures, and oils.

One of the most important things to consider when choosing a rigid-flex manufacturer is their experience. A manufacturer with extensive experience in this field is more likely to provide quality products and excellent customer service. In addition, an experienced manufacturer is more likely to keep up with industry changes and adapt to new challenges.

Choosing a rigid-flex manufacturer that offers one-stop services can be a great way to save time and money. These manufacturers can provide a wide range of services, from design and layout to prototyping and full-scale production. Additionally, they can offer you the right amount of flexibility to meet your needs and budget.

A reliable rigid-flex manufacturer will have a dedicated team of engineers that can handle any project. They will also be able to deliver your circuit boards on time and within budget. In addition, they will be able to provide you with all the necessary documentation and engineering support that you need for your project.

No Comment