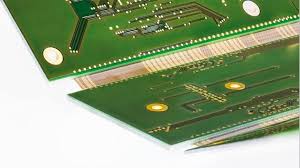

Controlled Impedance in Flexible PCB Boards

Impedance in Flexible PCB Boards

As a design engineer, you need to ensure your flexible PCB maintains signal integrity and offers high performance. Impedance control is a key factor in this equation, as it guarantees your product can handle high-speed signals without losing performance. To achieve impedance control, you need to keep your signals separated, trace length matching, and eliminate bypass capacitors and vias. Getting these things right requires an understanding of what is required for controlled impedance in flex circuits and the best practices to follow.

Impedance is the resistance a circuit board’s conductors and reference planes place on current flow, and it is essential for ensuring proper flex signal transmission. If a flexible pcb board signal traces have different impedances, they will experience reflection that will interfere with and possibly degrade the signal.

Controlled impedance on a flex PCB is achieved by adjusting a number of factors, including the flex material’s dielectric constant and loss tangent, the tracing geometry, and layer stackups. A flex circuit’s core and coverlay materials are especially important because they impact the final signal impedance, and they also determine how well the flex circuit can be mechanically bent.

Controlled Impedance in Flexible PCB Boards

Using the wrong material for your PCB could significantly affect its flexibility. For instance, using a flex material with a low dielectric constant will reduce the flex circuit’s mechanical strength. This can lead to a loss of flexibility and a reduction in the quality of the resulting board.

A flex or rigid-flex PCB’s core thickness can also significantly affect the impedance of the board. A thicker core is better for maintaining controlled impedance, but it can create problems in mechanical bends. A thin core may not have enough room to separate the traces, which increases the likelihood of crosstalk and signal attenuation.

To ensure you’re getting the most out of your flex PCB, choose a material with a higher dielectric constant to allow for a thinner core. In addition, you should choose a flex or rigid-flex PCB that has continuous ground layers, which will help improve the reliability of the flex circuit’s high-speed signals.

Flexible printed circuit boards (PCBs) have become indispensable in modern electronics due to their versatility and adaptability to various applications. These flexible circuits are often used in devices where traditional rigid PCBs would be impractical, such as wearable technology, medical devices, and automotive applications. However, along with their numerous advantages, flexible PCBs also present unique challenges, one of which is impedance control.

One of the primary reasons impedance control is essential in flexible PCBs is to maintain signal integrity. In high-speed digital applications, signals travel at incredibly fast speeds, and any impedance mismatch along the transmission line can lead to signal distortion, reflections, and ultimately, data errors.

Impedance in flexible PCB boards refers to the opposition that an electric circuit offers to the flow of alternating current (AC). It encompasses resistance, capacitance, and inductance, and is crucial for ensuring signal integrity and minimizing signal loss in high-speed digital and high-frequency analog circuits.

No Comment